Hydraulic valve blocks & manifold blocks for tail gates and lift gates – Essential components of modern hydraulic systems

Hydraulic valve blocks and manifold blocks are key components in the hydraulic systems of tail gates and truck lift gates. They precisely control the hydraulic oil flow, ensuring smooth and balanced movements of the lifting mechanism. Without these components, precise control of modern tail gates and lift gates would not be possible. They enable loads to be lifted, lowered, and positioned safely – a decisive factor for safety and functionality in daily use. In this category you will find valve blocks and distribution blocks designed for precise control of hydraulic oil flow in tail gate systems, supporting smooth and controlled movement sequences. At SULEJ Ladebordwand, we rely on tested components that ensure reliable performance and high operational safety under real operating conditions.

Design and function – How hydraulic valve blocks control the lift gate hydraulics

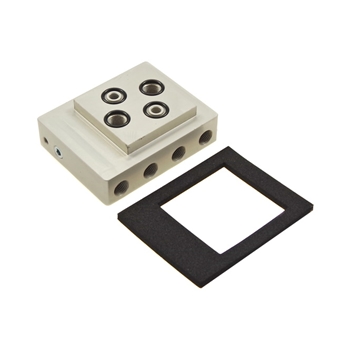

A valve block is a compact unit that combines several valves in one housing. These valves regulate pressure, flow rate, and direction of hydraulic oil that drives the lift gate or tail gate. Various valve types are used, such as directional control valves, pressure relief valves, or check valves. Depending on the system requirements, valve blocks can be configured individually to enable functions such as lifting, lowering, or locking.

Valve blocks are typically made of aluminum or steel and designed for high pressure resistance and corrosion protection. Precise manufacturing and perfectly matched sealing systems reduce leakage losses and increase the efficiency of the entire hydraulic system.

Variety of types – From standard solutions to customized hydraulic systems

Valve blocks come in different designs – from compact single valve blocks to complex multiple manifold blocks. We offer both standardized solutions and customized systems tailored precisely to the needs of workshops, fleet operators, and vehicle manufacturers. Whether compact construction for tight installation spaces or modular systems for flexible expansion – the variety of models covers almost all application areas. On request, electronic controls can also be integrated to equip modern truck lift gates with diagnostic or automatic functions.