Printed circuit boards (PCBs) for tail gates & lift gates – Precision meets power

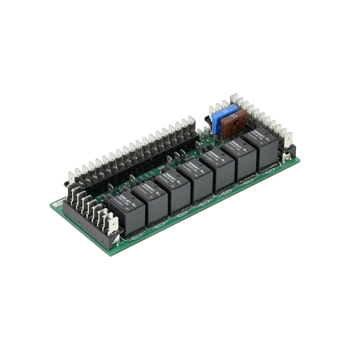

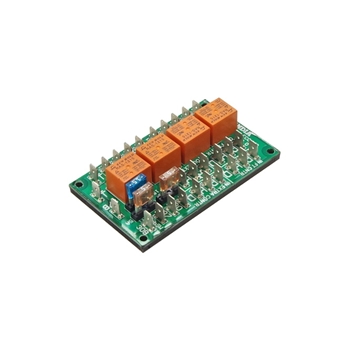

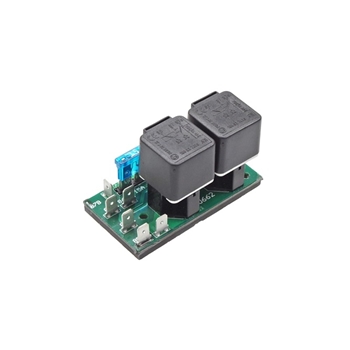

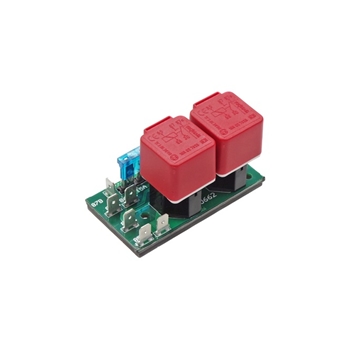

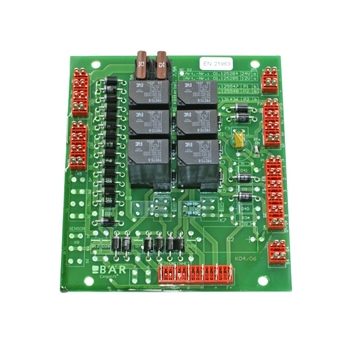

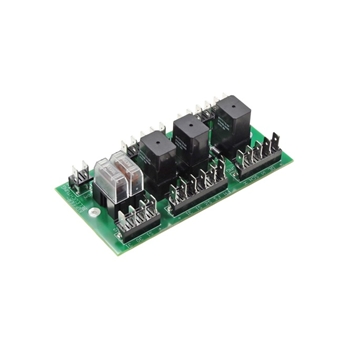

In the dynamic world of logistics and passenger transport, smooth processes, maximum safety, and digital precision are indispensable. Whether for loading sensitive goods or providing safe passenger access – modern tail gates and lift gates operate daily under high demands. Complex printed circuit boards coordinate the hydraulic systems, serving as the digital heart of each lift gate or tail gate. They control all lifting, lowering, and locking movements, ensuring safety, efficiency, and reliability. For private users, workshops, fleet operators, and B2B clients, they are a key factor for smooth workflows and long-term operational readiness. In this category you will find main control boards designed for the central control of modern tail gate systems, supporting precise and reliable coordination of all functions in operation. At SULEJ Ladebordwand, we rely on tested components that ensure stable control, high reliability and long-term availability under real operating conditions.

Control boards – The command center of every tail gate and lift gate

Each tail gate and truck lift gate functions through perfect interaction between mechanics, electronics, and hydraulics. These systems work seamlessly to deliver safe and controlled lifting motions. At the core is the printed circuit board, acting as the electronic brain of the system. It monitors all signals, controls hydraulic pressure and flow direction, and connects mechanical and digital control logic. This synergy guarantees reliability, safety, and maximum efficiency in logistics, passenger, and commercial use.

Digital conductors – How printed circuit boards orchestrate every movement

The role of a printed circuit board can be compared to a conductor leading an orchestra. It receives input – from control panels or sensors – and translates it into precise commands for actuators. Every movement, from lifting to locking, is harmonized. Sensors continuously report system status back to the printed circuit board, which immediately corrects deviations to ensure flawless performance. The result: reliable operation and maximum safety during daily use.

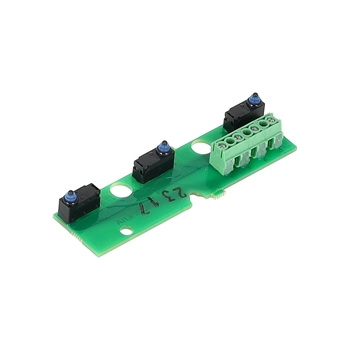

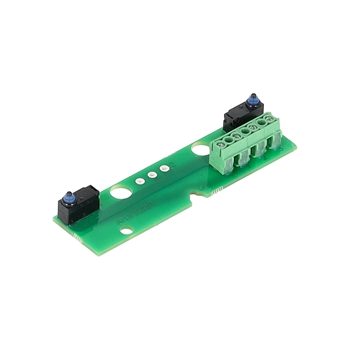

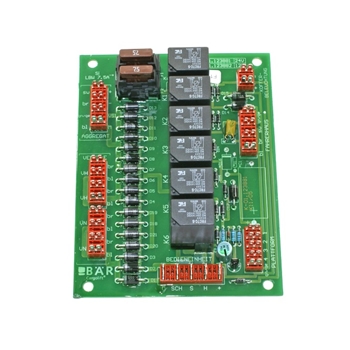

Design and materials of modern printed circuit boards for lift gates

Printed circuit boards vary depending on lift gate model and application. While standard versions handle essential hydraulic control, advanced types offer radio remote operation, integrated diagnostics, or safety shutdowns. Each PCB can be tailored for the specific vehicle setup. Electronics are exposed to vibration, moisture, and temperature extremes – therefore, coated surfaces and corrosion-resistant components ensure stable performance and long life. When selecting spare parts, always rely on tested and compatible solutions. SULEJ Ladebordwand stands for durable printed circuit boards built for heavy-duty, daily operation.