Tail lift sensors for lift gates – Precise control and operational safety

At SULEJ Ladebordwand, we understand how crucial precise sensor technology is for the safety, reliability, and durability of modern tail lifts. In today’s transport and logistics industry, efficiency and safety depend directly on accurate control and sensor systems. Especially in tail lifts and lift gates, sensor systems play a central role: they act as the “nervous system” of each unit, detecting motion, tilt, and position while reliably coordinating all operations. These precise lift gate sensors connect hydraulics and electronics into one perfectly tuned system. Whether for workshops, fleet operators, or private customers – high-quality sensors are key to ensuring functional safety, longevity, and performance of every lift gate.

Function and purpose of sensors – Precise control for every tail lift

Sensor technology monitors and controls every movement of the lift gate with the highest precision. It detects physical conditions such as position, angle, and movement, converting them into electrical signals evaluated by the control unit. As a result, platforms move with millimeter accuracy, obstacles are detected early, and overloads are reliably prevented. From initialization to lifting, lowering, and locking, various sensor types work together: foot switches register operating impulses, tilt switches detect the exact platform alignment, while proximity and reed sensors monitor motion limits and end positions. Angle sensors ensure that every movement is controlled, safe, and efficient.

Variety and structure – Overview of sensor components

The world of tail lift sensors is diverse. Each component fulfills a specific task within the system:

Foot switch electronics: control the opening and closing of the platform and the activation of lighting. They signal when the lift gate is fully closed and send additional control signals through the foot pedal.

Tilt switches: detect the tilt position of the platform and signal when the tail lift is closed. They also control opening, closing, and lighting functions, ensuring correct alignment.

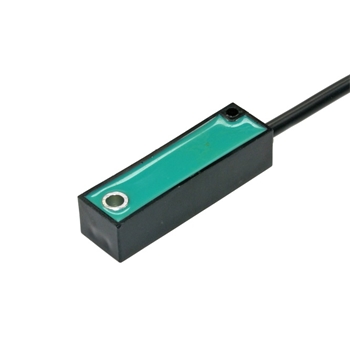

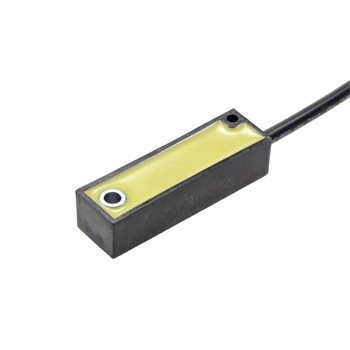

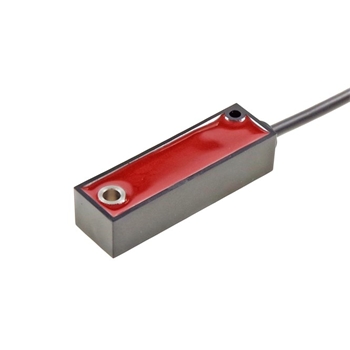

Reed sensors: operate magnetically, monitoring opening, closing, and lighting functions. They send signals about the closed position and tilt of the platform to the controller.

Proximity switches and initiators: detect objects contactlessly during platform movement and prevent collisions by triggering automatic stop signals.

Angle sensors: measure tilt angles precisely to ensure accurate positioning of the lift gate.

All components are made from high-quality materials such as durable plastics, corrosion-resistant metals, and robust housings. Designed for daily use under vibration, temperature changes, humidity, and dirt, they guarantee maximum service life and functional safety.