Cables for tail gates and lift gates – The electrical backbone for safety and reliability

In modern commercial vehicle technology, it’s often the inconspicuous components that determine performance, efficiency, and safety. Tail gate cables form the electrical nervous system of every truck lift gate – ensuring stable power and signal transmission between control unit, motor, and hydraulic system. Without them, even the most advanced lift gate would stop working. Whether in daily logistics, workshop service, or fleet maintenance – the quality of the installed cables determines reliability, safety, and service life of the entire system. At SULEJ Ladebordwand, we rely on precisely manufactured, durable cable systems designed to withstand vibration, moisture, and temperature fluctuations – delivering lasting performance and maximum safety.

The lifelines of your lift gate – Design, function, and load capacity

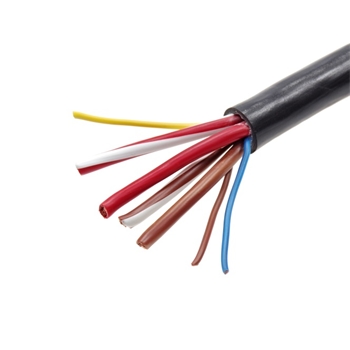

A cable in a tail gate is far more than just an electrical wire. It transfers power and control signals between control panel, electronics, and hydraulic unit with precision and minimal loss. Inside, high-conductivity copper strands ensure low voltage drop, while the durable outer jacket made of elastomer or PVC protects against abrasion, chemicals, UV rays, and moisture. Material quality directly affects efficiency, safety, and service life: premium cables endure years of heavy-duty use, while inferior replacements can cause signal loss, short circuits, or system failures. For commercial truck lift gates, certified cable quality is key to reliability, safety, and long-term cost control.

The right tail gate cable for every application and lift gate system

The variety of tail gates and lift gates requires specialized cable solutions. Each cable is designed for a specific purpose – from power transmission to signal control:

- Spiral and coiled cables: Flexible connections between vehicle and platform controls, providing stretch and stability during movement.

- Platform cables: Extra-durable types for fixed installation on the loading platform, reinforced for abrasion and mechanical wear.

- Control cables: Transmit fine control impulses between the operating panel and control board with shielding against electromagnetic interference.

- Power cables: Deliver energy to the motor and hydraulic unit with thick cross-sections for continuous load handling.

- Adapter cables: Bridge different connector systems – essential for retrofits, repairs, and system adaptations.

Common plug types include AMP 5-pin, AMP 6-pin, AMP SuperSeal, APD, Deutsch, and CONI connectors, as well as flat and round plugs. The correct plug ensures secure contact, high protection class, and electrical safety – even under vibration, dirt, or moisture.