Hydraulic Aggregates: The powerful heart of the truck tail gate

A high-performance hydraulic aggregate is the power center of every tail gate. It combines motor, pump, tank and valve technology into a compact unit and generates the hydraulic pressure required for all lifting, lowering and closing movements. In this category, you will find hydraulic aggregates designed for professional use in the transport and logistics sector. Truck lift gates rely on the same basic principle: the power pack converts electrical energy into hydraulic output and ensures that loads are moved safely, controlled and efficiently under various operating conditions. At SULEJ Ladebordwand, the focus lies on durable and maintenance-friendly components that convince in daily operation through reliability, stability and consistent performance.

Hydraulic power transmission: How a hydraulic aggregate works inside a truck lift gate

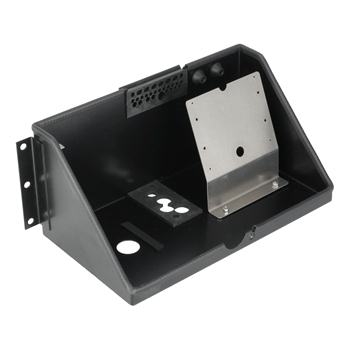

The basic principle of a hydraulic aggregate is the controlled conversion of electrical energy into hydraulic performance. An electric motor drives a precisely dimensioned hydraulic pump that draws hydraulic oil from the tank and supplies it under high pressure. Through control valves, the pressurized oil is then routed to the hydraulic cylinders mounted on the tail gate. There, the hydraulic pressure is converted into linear motion — the platform lifts, lowers or closes reliably and with constant force. The valve control enables precise metering of the oil quantity, allowing all movements to run smoothly, evenly and reproducibly. The quality of the core components — motor, pump, valves, tank and sealing systems — directly determines the performance, efficiency and reliability of the entire hydraulic system in daily use.

Designs and materials: Construction for different application requirements

Hydraulic power packs are available in various designs to reliably meet the requirements of different vehicles and operational scenarios. Key technical parameters include operating voltage, tank volume and the performance characteristics of the installed pump. Light transporters and flatbed vehicles typically use 12-volt aggregates, while heavier commercial vehicles generally operate with 24-volt systems. The size of the hydraulic oil tank is also crucial: it must match lifting height, platform dimensions and number of hydraulic cylinders to ensure sufficient oil volume is available for all movement sequences at all times. In truck lift gates, thermal stability of the aggregate also plays an important role, as many systems operate in intensive continuous use and are therefore exposed to higher load cycles. Equally important is the alignment of flow rate and permissible pressure range. Only when these values match the required lifting capacity and operating speed of the tail gate does the hydraulic system work efficiently and without unnecessary heat generation. Robust materials such as steel or high-grade aluminum alloys are used for housings, pump units and motor components. Corrosion-resistant coatings and durable sealing systems additionally protect the aggregate against moisture, dirt and temperature fluctuations. As a result, delivery performance remains stable even during intensive continuous use, and the operational safety of the entire system is ensured over the long term.