Stickers & Signs for Tail Gates and Lift Gates – Clear Information for Safe Workflows

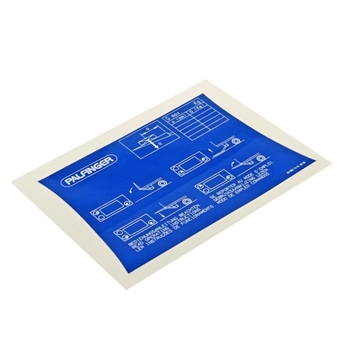

In day-to-day transport and commercial vehicle operations, clear information is a key safety factor. Stickers and signs on the tail gate – such as Safety Stickers, Operator Plates, Load Diagrams, Type Plates, Manufacturer Plates and Inspection Plates – provide safety notices, explain operating functions and permanently secure important equipment data. This supports safe handling, reduces operating errors and helps implement company requirements and inspection obligations reliably.

Whether in fleet operations, in the workshop or on your own vehicle, clearly visible markings improve workflows, help prevent overloading and ensure a professional overall appearance. This category is intended for workshops and fleets – also as replacements when existing markings are damaged, missing or illegible.

Function and Importance of Markings on the Tail Gate

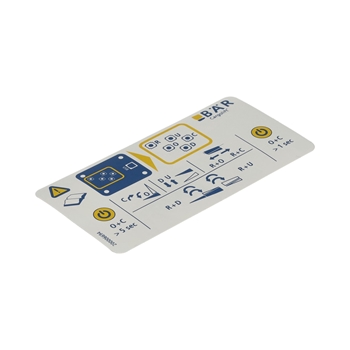

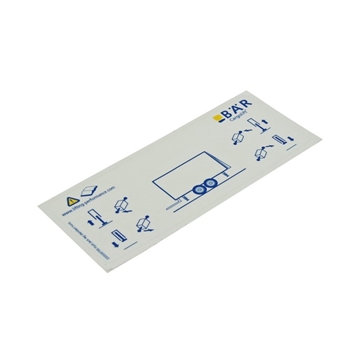

Marking elements are the direct source of information on the equipment. They warn of hazardous areas, provide operating instructions and make load limits transparent. Especially with changing operators or in time-critical loading situations, clear labelling helps keep processes standardised and prevents risks caused by misinterpretation. Pictograms and short operating notes help users understand functions quickly without having to search or interpret for long.

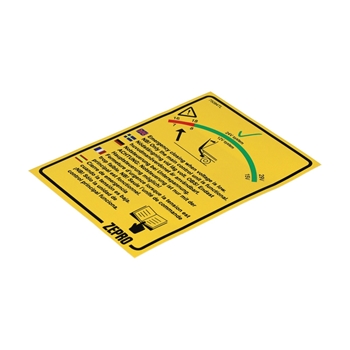

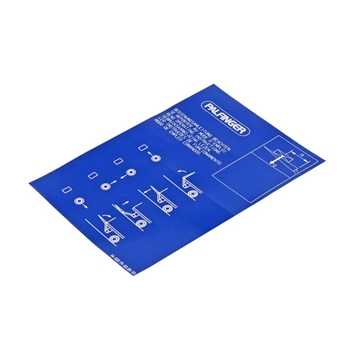

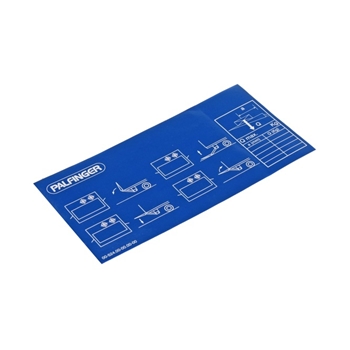

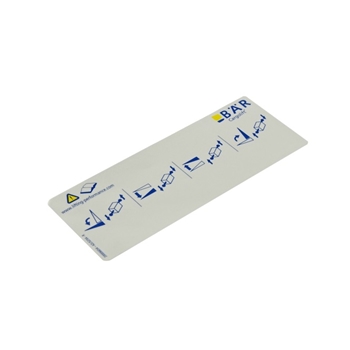

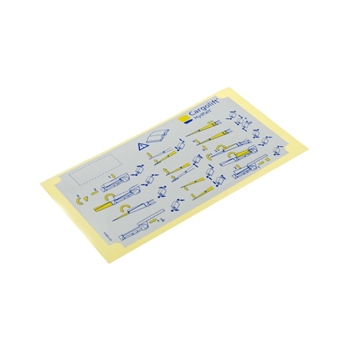

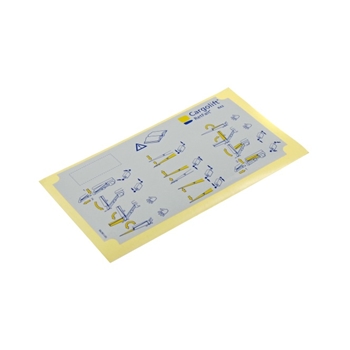

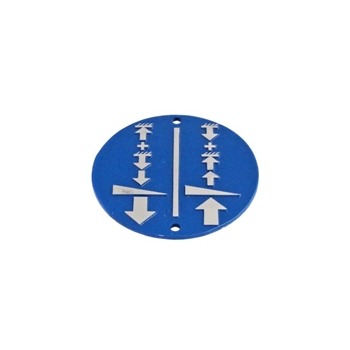

Safety Stickers, Operator Plates and Load Diagrams Working Together

Safety Stickers on the tail gate mark pinch points, hazardous zones and required clearances. Operator Plates explain functions and directions of operation, typically via pictograms and short text. A Load Diagram is one of the most important markings because it shows the permissible capacity depending on outreach and position. This helps prevent overloading, protecting both operational safety and the service life of the tail gate. Together, these markings provide clear, practical guidance exactly where it is needed.