What are roll-stop safety flaps on tail lifts used for?

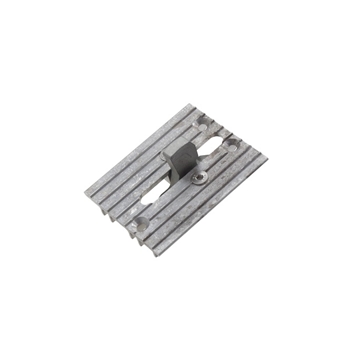

Roll-stop safety flaps on tail lifts are used to ensure safety during loading and unloading. They prevent roll containers, pallet trucks, or other rolling cargo from unintentionally rolling off the platform of the tail lift or lift gate.

Main aspects at a glance:

• Protection against rolling off: When raising or lowering the tail lift, the flaps manually block the end of the platform and act as a small stopper / barrier.

• Increased safety for operating personnel: Especially when handling heavy or bulky loads, roll-stop flaps significantly reduce the risk of accidents.

• Easy to retrofit: Many tail lift spare parts, particularly safety flaps, are available as original parts or matching variants and can be retrofitted on many models without issue.

Roll-stop safety flaps for tail lifts at a glance

Roll-stop flaps are generally made of durable steel or aluminum. The materials are carefully selected to withstand daily exposure to weather, mechanical stress, and constant use. Some versions have anti-slip surfaces that offer additional safety through improved traction. Roll-off protection systems are particularly common in food retail, parcel delivery, furniture logistics, and event services; anywhere rolling cargo is regularly moved. Similar flap solutions are also used as safety devices on vehicle-based lift systems for wheelchair users.

Maintenance, retrofitting, and legal requirements

Regular maintenance of roll-off safety systems is essential. Defective, damaged, or stiff-moving flaps can seriously impair safety during loading and unloading. Our range includes numerous high-quality original tail lift spare parts, including 100% matching roll-stop flaps for many common manufacturers and models. Whether BÄR Cargolift, DAUTEL, DHOLLANDIA, or MBB Palfinger, retrofitting roll-stop safety flaps is often easily possible. Functioning safety flaps are frequently subject to legal and operational requirements. In Germany, the DGUV Regulation 70 "Vehicles" applies. Insurers and major clients also rely on compliance with such safety standards and demand that these components be in perfect working condition.