Platform tips for tail gates and lift gates – Protection, stability and durability at a glance

In demanding transport operations, precision in every detail counts. The tail gate is more than just a working element – it is the interface between vehicle, cargo and ground. Platform tips play a key protective role here: they absorb impacts, prevent cracks and maintain the stability of the lift gate even under heavy use. At SULEJ Ladebordwand, years of maintenance and system experience flow directly into the design and selection of these components – ensuring longer service life and maximum reliability in everyday use.

Function of platform tips – Protection against wear, impact and material fatigue

Platform tips do much more than act as simple edge protection. As the front contact point of the truck lift gate, they absorb shocks, shear forces and vibrations, distributing energy evenly to prevent cracks, deformation or stress in the platform. Their tapered shape minimizes the gap between the platform and the ground – ideal for precise, safe docking to ramps, loading areas or uneven surfaces. This maintains the structural integrity of the tail gate even during intensive use. In practice, rounded ends also reduce operator injury risk, prevent paint damage and minimize abrasion on goods. In short: platform tips are small components with a big impact – they increase operational safety, reduce maintenance costs and ensure long-term durability of the entire system.

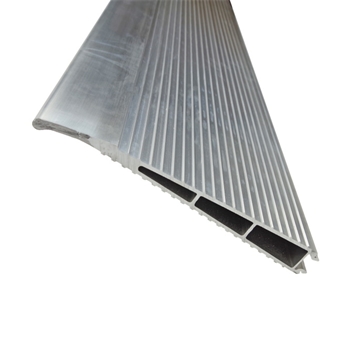

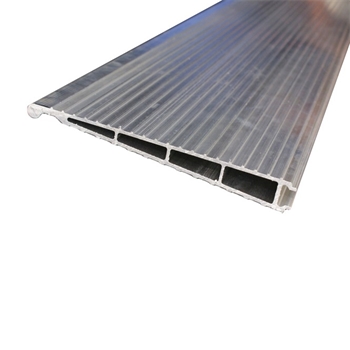

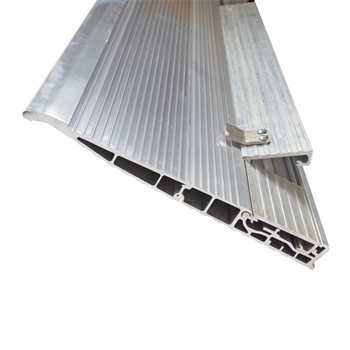

Material quality and construction – Durable components for every truck tail gate

Depending on the platform type and operating conditions, platform tips differ mainly in their design and safety features. Versions with roll-off protection have a central foldable edge that can be raised when needed. In its resting position, it lies flat for smooth ramp access. When raised, it effectively prevents roll containers, pallet trucks or pallets from rolling off the platform – essential for heavy-duty loading or varying dock heights. Flat-end tips without roll-off protection, on the other hand, provide a permanently even edge, perfect for applications requiring a seamless transition. Both variants are made of high-strength, weather-resistant aluminium, precisely manufactured for daily use on tail gates and lift gates. They offer reliable edge protection, reduce impact loads and enhance the safety and service life of the entire system.