Power relays for tail gates and truck lift gates – Switching power meets precision

In professional transport operations, reliability, safety, and precise control matter in every situation. Whether loading and unloading heavy goods or operating continuously under changing conditions – Every tail gate and truck lift gate depends on perfectly coordinated electrics. This is where power relays play a central role. They are the unseen heroes of the control system and ensure that every electrical impulse is implemented precisely. Without them, even the most modern tail lift comes to a standstill. In this category, you will find power relays designed for the requirements of tail gate electrics and supporting reliable switching and control in daily operation. At SULEJ Ladebordwand, we know from years of experience: A reliable power relay determines operational safety, service life, and efficiency of the entire loading system.

The power relay – Switching center of every truck tail gate

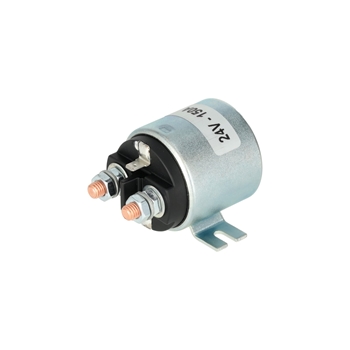

Every tail gate works only through the interaction of mechanics, hydraulics, and electrics. While hydraulics and mechanics provide movement, power relays handle the precise control of these processes. In the tail gate sector, power relays are also referred to as starter relays or high-current relays depending on the manufacturer, because they switch the high-current circuit between the control unit/controller and the drive. As central switching units, they connect the control unit to the high-current circuit, switch electric motors on or off, and protect the electronics from voltage spikes.

Power relays stabilize current flow, protect the control system from voltage spikes, and enable smooth, controlled movement sequences of the truck lift gate. This keeps the lift gate reliable, precise, and efficient – Even under continuous load.

More than just a switch – The function of power relays in detail

A power relay is an electromagnetically controlled high-current switch. A weak control signal from the control unit activates a solenoid coil that generates a magnetic field. This pulls a contact and closes the high-current circuit – The motor of the tail gate receives power and can raise or lower. This indirect switching protects the sensitive control electronics from current peaks and ensures safe, controlled platform movements. This creates a durable, low-maintenance connection between the control unit, electric motor, and hydraulic power pack.