Roll stops on the tail gate – Components for securing rolling loads

Roll stops provide a critical safety function on the tail gate. They prevent rolling transport devices such as roll containers or carts from unintentionally leaving the platform and reduce additional load on surrounding mechanical structures. Within this category, the focus is on roll-off flaps, as they represent the primary component securing the platform edge. SULEJ Ladebordwand uses certified components that support stable load positioning and a controlled movement pattern throughout all lifting and lowering sequences. A roll-off protection system prevents uncontrolled rolling movements during the lift or lower process and significantly increases operational safety.

Defined blocking action of the roll-off flap – Safety at the platform edge

Roll-off flaps act as a mechanical barrier at the outer platform edge. During lifting and lowering, they prevent uncontrolled rolling of transport equipment and stabilize the load on the platform. Depending on the system, these flaps move manually or automatically into the locked position and reliably block the rolling path. On a lift gate, roll stops secure the transition between the platform and the ground and ensure stable load guidance. An intact roll-off flap is an essential component for defined and safe platform movement.

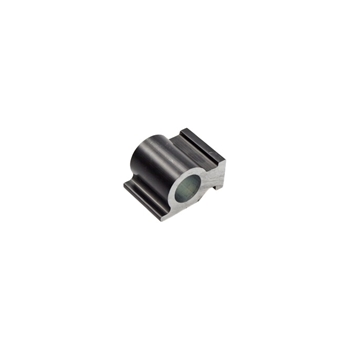

Construction types and materials – Variants of the flap mechanism

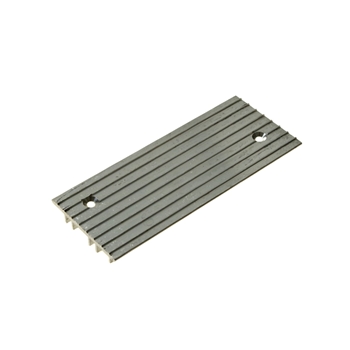

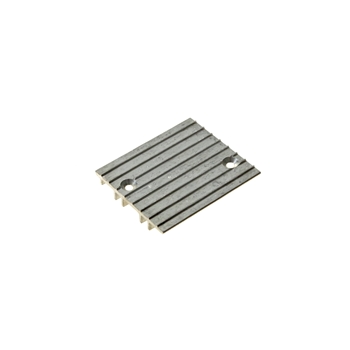

Roll-off flaps are available in various configurations. One-piece versions cover the full platform width, while two-piece systems allow segmented use of the platform edge. The flap is moved manually into the securing position, either by hand or by foot actuation at the platform edge.

For tail gate systems, roll stops are typically manufactured from aluminum alloys, combining low weight with sufficient structural strength. Steel is used locally for hinges, reinforcement plates or other safety-relevant connection components. Corrosion-resistant finishes such as powder coating increase durability against moisture and mechanical stress.

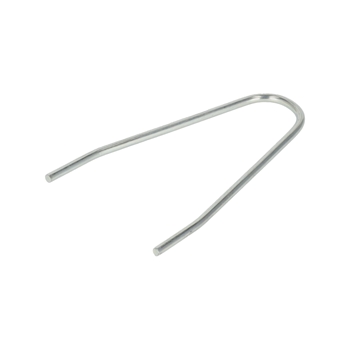

On a tail lift, varying forces act on the flap, hinges and mounting points throughout the lifting and lowering cycle. Hinges and locking elements must withstand repeated load changes to maintain reliable roll-off protection. The correct component is selected according to platform width, installation conditions and the structural requirements of the system.